Additionally, it’s critical to distinguish between coolant pumps used in machine tools and those used in automobiles and nuclear reactors. Several little details set them apart from others who live in practice, even though every one of them operates by circulating a coolant throughout. For instance, a coolant compressor for a pressurized water reactor is more complex and technically demanding since it must be capable of transporting heat from a device that generates water via various pressure channels. The function of the cooling tower pumps is simpler in cutting machines and automobile engines since it is just required for circulating coolant, regardless of pressure variances.

Operation

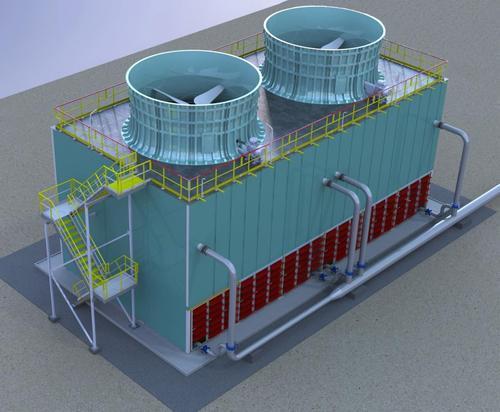

A cooling facility constitutes a massive heat transfer device that uses cooling water to eliminate heat from refrigerant that has been applied to buildings, machinery, and other industrial processes. A tiny amount of the conditioning water’s evaporation as it comes into contact with air lowers the temperature. To remove heat, boiling water compared to a commercial might either run straight through the cooling station or encounter an exchange vessel or evaporator.

Specialization

The fluid that cools the system pump’s job is to make sure that refrigerant is dispersed uniformly throughout the building. The word “coolant” is frequently replaced by the term “heat transfer fluid” in industrial operations. Since coolant pumps are employed in so many different sectors, they have developed a variety of distinct specializations. However, a pump for cooling tower is often a multiple-phase submersible pump that uses In plainer terms, a method of cooling pump transfers electricity to the circulation through the rotation of several shaft-driven impellers while being submerged in water.

Capacity requirements

It may be challenging to determine whether you truly need a coolant compressor because of how many industrial uses there are (anything from reactor feeds to commercial washing machines), since it may be much more challenging to limit it to a particular type. However, choosing the ideal coolant pump is not too difficult after your movement, pressure, and capacity requirements have been determined. The versatility of the company line of SPK refrigerant pumps, on the other hand, makes them a viable option in a variety of circumstances if you are still confused about the technical aspects. The procedure for cooling is assisted by cooling fans inside the structure, and the drifting eliminators remove droppings of water that are formed in the skyscraper’s air stream throughout evaporation.

Consideration

Throughout large-scale conditioning activities like electricity production, natural gas and petroleum refining, and geothermal power plants, cooling systems are often employed. The needed coolant temperature ought to become a key consideration when selecting a cooling system or refreshing tower.

Depending on the localized wet bulb circumstances and the surrounding air temperature, chilling tower temperatures change. When employing a tower with cooling, the average low temperature of cooling fluid in the summertime seldom ever goes beneath 75 to 80 degrees Fahrenheit. All year round, chillers may attain normal temperatures of 70°F or below. If intended to handle such circumstances, certain chiller models might enable for chilling temperatures between 70 and 100 degrees Fahrenheit. A refrigeration unit can often retain a temperature that is closer to the target temperature threshold depending on the system architecture.